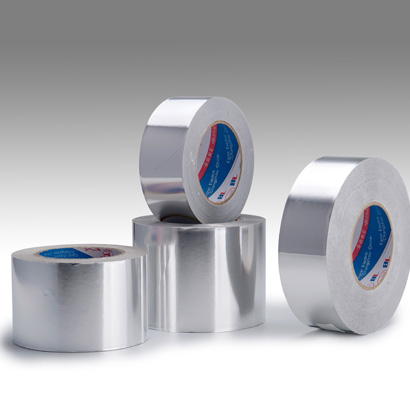

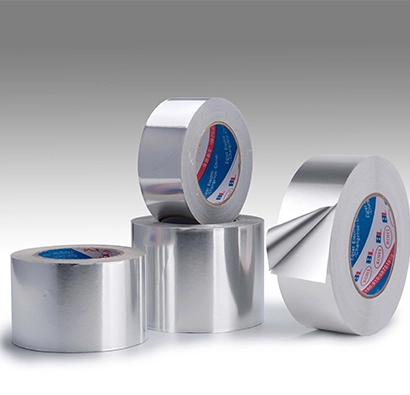

Laminate Aluminum Foil Tape

The tape base material is two layers material, aluminum foil joint with plastic film. Normally we use PET, PE or BOPP film. And coat with aggressive solvent or water based acrylic adhesive. Protected by an easy-release silicone paper liner. The aim to use 2 layer material, on one hand to save cost, on the other hand to improve elongation rate and tensile strength. Also, provides outstanding moisture barrier. In addition, it can be either easy hand tear or hard tear, according to customers request. Important to realize, the combination of baking material ensures high flexibility and conformability. The application for this tape is mainly used for refrigerator cooling tube attachment.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย Indonesia

Indonesia