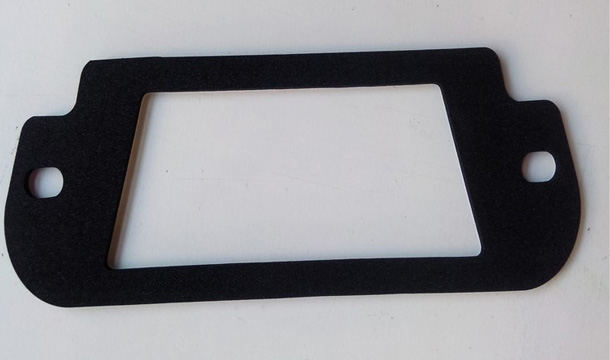

Uses die cutting machines to stamp different shapes like square, round or irregular shapes. The base material can be foams, aluminum foils with liner, rubbers, etc.

Uses die cutting machines to stamp different shapes like square, round or irregular shapes. The base material can be foams, aluminum foils with liner, rubbers, etc.

It is a manufacturing process, to make big jumbo to small logs or cut rolls. The base material can be all type of tapes, such as aluminum foil tape, masking paper tape, etc. The benefit is for wholesaler to cut different width of tape from logs.

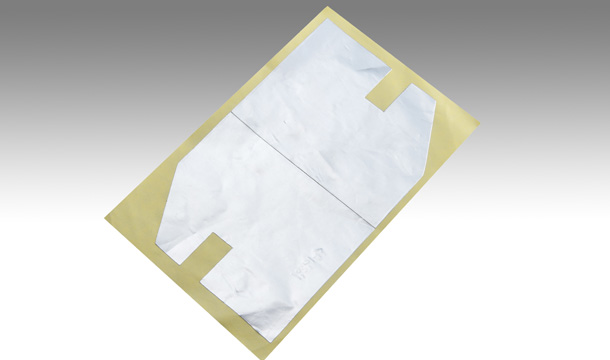

It is similar to die cutting, but not so similar. Die cutting is penetrating through the liner, but kiss cutting not penetrating the liner. It is stamped by a metal die or laser.

It is a very common and important manufacturing process, to make jumbo rolls or log rolls to small thinner cut rolls. It is a vital process from half finish product to finish product.

It is a combining process to put 2 or 3 layers material binding together with special glues. For example, aluminum foil laminated with BOPP. The aim is to improve elongation rate, tensile strength, or save cost.

Egret also offers individual roll or multi roll shrink wrapping plastic packaging service. It makes the tape neater and cleaner looking, avoid damage and contamination. Plus, it can be closed with paper label. Normally the service is requested by super market or retailers.