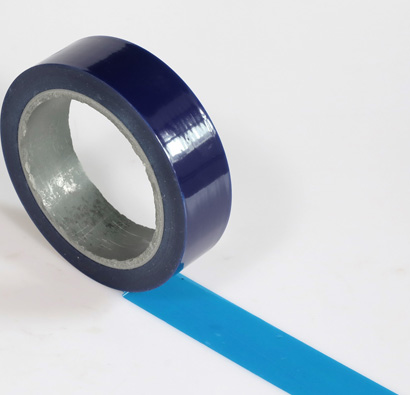

In the highly competitive home appliance industry, protecting surfaces during manufacturing, transport, and installation is essential. PE Protection Film, also known as polyethylene surface protection film, is a trusted solution for safeguarding metal, glass, and plastic finishes on refrigerators, ovens, and other appliances. Egret Mfg offers a high-quality blue PE protection film that combines excellent physical properties with clean removability—making it ideal for appliance OEMs and suppliers.

PE protection film from Egret Mfg uses a blue polyethylene base, coated with either a water‑based adhesive or solvent‑based acrylic adhesive, without a silicone liner. This structure gives it remarkable stretchability, high elongation, and very strong hand-tearability, while its silicone backing ensures easy release when unwinding during production.

Because of these characteristics, Egret Mfg's PE film can conform tightly to irregular surfaces like appliance doors, curved metal edges, or exposed glass panels. The blue hue makes it easily visible during assembly, reducing the risk of installation errors. And best of all, when removed, it leaves no adhesive residue, preserving the pristine finish of appliances.

Glass Surface Protection

Appliance manufacturers commonly apply PE protection film to glass panels, such as refrigerator doors or control glass surfaces. During fabrication, shipping, and installation, these surfaces are vulnerable to scratches, dust, and abrasion. Egret Mfg's PE film shields these delicate surfaces without reducing clarity or leaving adhesive behind once the product reaches the consumer. This mirrors practices by other major protective-film providers in the industry.

Metal and Painted Surface Protection

Beyond glass, many appliances include stainless steel or powder-coated metal finishes. Egret's PE protection film works perfectly to protect these surfaces from scuffs and abrasion. Because of its excellent UV resistance and weatherability, it can also remain on exposed parts during transport without degrading.

Protective-film manufacturers note that low‑tack adhesives help maintain clean removal, even from highly finished metals.

Plastic Components and Molded Panels

Many modern appliances feature plastic or molded polymer parts—such as control panels, handles, or decorative inlays. Egret Mfg's PE film is especially suited for these because polyethylene has good chemical resistance and flexibility. The film's high elongation (≥ 180%) allows it to stretch and conform tightly around curves.

Once the appliance is ready for installation, the tape's silicone release layer ensures that the film wraps off easily and cleanly without damaging delicate plastic surfaces.

Minimize Scratches and Cosmetic Damage

By applying Egret Mfg's PE protection film early in the production line, OEMs prevent micro-scratches during automated handling or robotic processes. When products are transported or handled by installers, the film acts as a first line of defense against damage.

Cleaner Workflow & Zero Residue

Because Egret Mfg's PE film is formulated so it doesn't leave adhesive residue, final assembly and packaging remain clean and free of contamination. That helps reduce rework, cleaning time, and risk of blemishes on consumer-facing surfaces.

Cost‑Effective and Scalable

Egret Mfg manufactures its PE protection film in jumbo rolls, maximizing efficiency for high-volume appliance assembly lines. The material's softness and stretch also mean less waste: installers can hand-tear the film to perfectly suit their tasks without needing expensive cutting tools.

Long-Term Protection

Thanks to features like UV resistance and weather stability, the PE film can remain on the surface for extended periods without degrading. Egret reports that its PE film holds up under -20 °C to +80 °C service temperatures.

To illustrate how Egret Mfg's PE film stands out, consider comparable products:

3M Polyethylene Protective Tape 3105C – A clear PE tape often used for surface protection, but more visible than blue film, which may be less obvious on metal or glass.

Electro Tape PE Surface Protection Film – 90 Day UV – Offers weather resistance and UV stability, similar to Egret Mfg's product, but Egret Mfg's high elongation and tear performance give it an advantage in conformability.

Blue PE Protective Film for Marble & Glass – A similar color and application, but Egret Mfg's version is optimized

For appliance manufacturers and maintenance suppliers, PE protection film offers unmatched benefits: scratch resistance, flexibility, clean removal, and visual clarity. Egret Mfg's blue PE protection tape combines all these qualities into a film purpose-built for modern appliances, with high elongation, silicone release, and weather stability.

Whether covering glass doors, stainless steel panels, or molded plastics, applying Egret Mfg's PE protection film can significantly reduce damage, save labor in cleaning, and support a high-quality finish from factory to installation. Choose smart protection—choose Egret Mfg.